Application details of IXPE foam material and its composite products in automotive products

IXPE foam material has the following excellent physical properties:

Flame retardant: The IXPE foaming products can reach FMVSS302 standard, UL standard, HB, V-2, V-1, V-0 (HB UL94 plastic flame retardant grade inspection method).

Environmental protection: tested by SGS, the world's most authoritative organization, 100% of the IXPE foaming products have passed the EU ROSH environmental protection directive, free of peculiar smell and toxic substances.

Heat insulation: IXPE foam products independent cell structure, no air circulation, thermal conductivity ≤0.04W/m∙k.

Sound insulation: 100% airtight chamber, effectively reducing the sound intensity, excellent sound insulation, meeting STC-73, IIC-72 standards

Waterproof: water absorption rate is lower than 0.02g/cm2

Aging resistance: After being modified by electron irradiation, IXPE foaming products have good weather resistance and chemical resistance, and the aging time is more than 15 years.

Based on the above excellent physical properties, IXPE has been widely used in automotive products

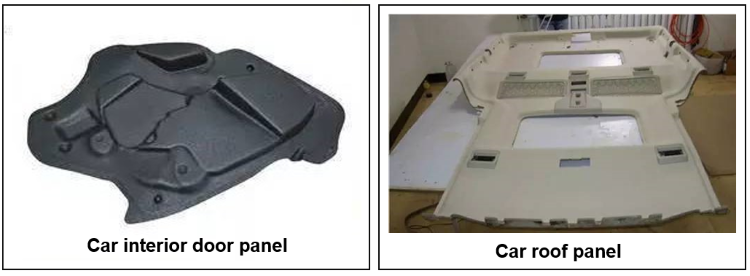

1. Car interior door protection sheet, car door panel waterproof membrane

Car interior door guard panels, previously used PP foam plastic panels. Due to its insufficient performance of aging resistance, shock absorption and heat insulation, and environmental protection, it has been replaced by IXPE foam materials. Its processing technology adopts: IXPE+non-woven PU-bonding-cutting-heating to reach the softening point-compression molding.

2. Canopy base material

The ceiling interior is an important part of the car interior. Its main function is to improve the decoration of the car. At the same time, the ceiling interior can also improve the heat insulation effect with the outside of the car; reduce the noise inside the car and improve the sound absorption effect; Improve the comfort and safety of occupants. As the sun shines directly on the roof of the car, the temperature of the top of the car is relatively high, so the heat resistance and weather resistance index of the roof interior are stricter. The materials and structure of ceiling interiors of different grades are different. In order to improve the effects of sound insulation, heat insulation, and noise reduction, considering various requirements, IXPE foam material can be the first choice for the ceiling substrate. The processing technology is: IXPE foam sheet + buffer insulation layer: rigid polyurethane foam plastic board + skin layer: fabric, TPO or PVC leather

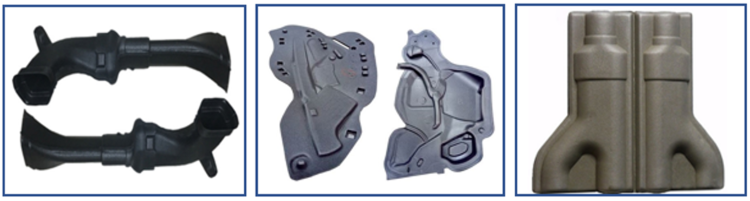

3. Sound insulation and heat insulation substrate for hood

Car hood sound-insulating and heat-insulating panels are often made of IXPE foam material with a thickness of 5MM and a magnification of 10-20 times. It is formed by hot pressing of molds. It can also be laminated with aluminum foil to enhance the effect of heat insulation and also block engine sound. Of delivery. The product also has the characteristics of safety and environmental protection, odorless, non-toxic, fire-retardant, waterproof and anti-corrosion, strong weather resistance, good flexibility, and free bending.

4. Sunshade products

High-intensity sunlight will cause the temperature in the car to rise sharply, making people feel unusually hot when entering the car, which is unbearable. In addition, the high temperature will damage the leather interior of the car, the electronic appliances in the instrument panel and other facilities. Therefore, in summer or when it is hot, the sunshade products of IXPE foam material are indispensable.

5. Sealing friction parts/gaskets

Sealing strip fixing system: rain gutter seal, B-pillar seal, door seal, rear window seal

Advantages: full contact and continuous sealing; reduce wind and road noise; reduce weight

Avoid the noise generated by traditional connection methods

Application: Used to fix automotive interior parts, such as decorative panels, instrument panels, glass frames, roof linings, etc. To be used for anti-scratch strips, pedal protection, rear fenders, nameplates, various trim doors and sides of the body Protection, guard board.

Due to the superior resilience and heat insulation and sound absorption properties of IXPE foam material, it is the preferred material for high-quality sealing and friction. IXPE foam material is convenient to process, easy to form, small thermal shrinkage coefficient, and non-deformation, and it is the protection of other complex parts of automobiles. The ideal product.

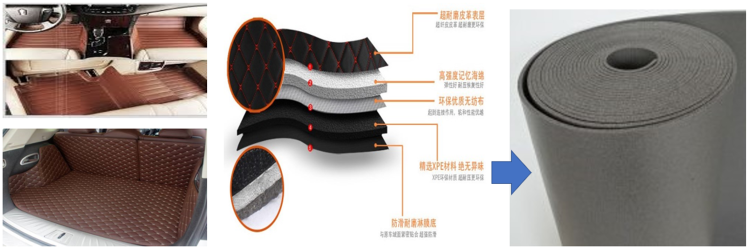

6. Car mat material and seat base material

Features:

Comfort: In addition to effectively improving shock absorption, sound absorption and heat insulation, the foot pads also have a texture and a more foot feel, reducing physical fatigue during driving.

Waterproof: strong waterproof performance, no water seepage on the surface, and can be washed repeatedly with water.

Flame-retardant: Different levels of flame-retardant products can be customized according to needs, effectively preventing open flames and cigarette butts from burning.

High resilience: The product has a strong sense of three-dimensional design, does not move or deform.

Super quiet: It is tested according to European standards, and its FIIC (performance index) minimizes reverberation and noise.