Application of XPE/IXPE Foam Coil in Automobiles and Several Processing Methods

XPE and IXPE foam materials are provided to automotive secondary suppliers as a single material. The materials can be applied to roofs, door panels, floor mats, trunk mats, engines, sun visors, pipe protectors, etc.

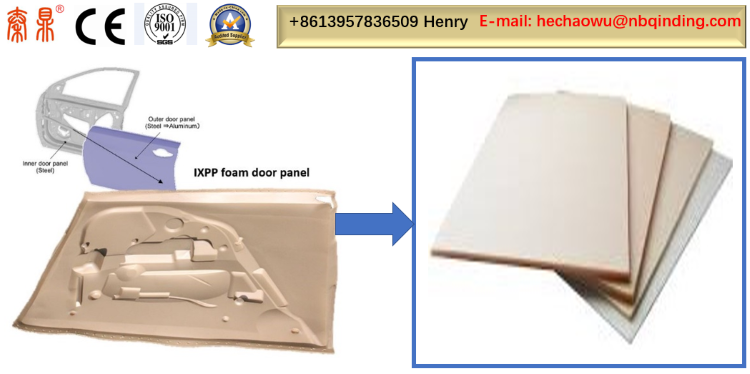

1. Door guard plate inside the car.

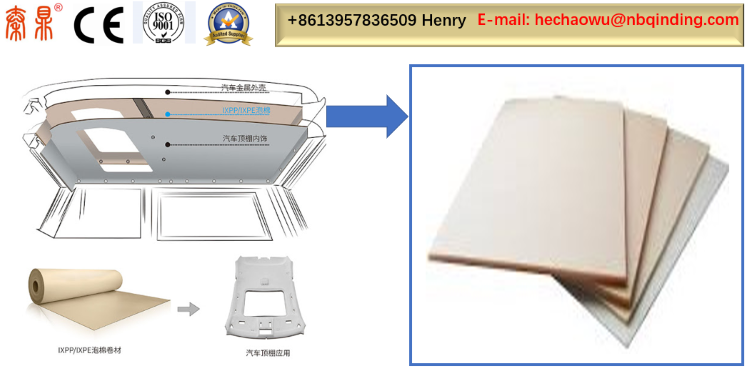

2. Roof insulation: The previously used roof insulation materials (PU, EPE, EVA and other foam materials) are easily deformed or exposed to the sun for a long time, so they have been weathered into powder. XPE/IXPE foam has become the most popular alternative. The ceiling board processed by XPE/IXPE foam is mainly made of composite flannel as interior parts, and then formed by hot stamping or cold stamping and hot pressing, which has a good molding effect and beautiful appearance.

3. Heat insulation pad: The heat generated by the engine of the car has seriously affected the comfort of the car. Due to IXPE/XPE foam's excellent thermal and heat resistance, XPE/IXPE foam is designated as the only thermal insulation mat-processed material. It is usually XPE/IXPE foam heat composite aluminum film and then compression molding.

4. Floor mats, luggage mats: floor mats and luggage mats generally use low-magnification XPE foam, molded by flame compound LDPE compression molding.

5. Sealing friction parts: Due to its superior resilience and thermal insulation and sound absorption performance, XPE/IXPE foam is the first choice material for high-quality sealing and friction.

6. Other plastic molded parts: XPE/IXPE foam is easy to process, easy to form, has a small heat shrinkage coefficient, and is not deformed. It is an ideal material for the protection of other complex parts of automobiles