-

07-21 2023

Development and application of XPE foam material in XPE floating mat

The application of the floating blanket on the water utilizes the characteristics of closed-cell foaming, hydrophobicity and light weight of XPE foam material and IXPE foam material. In addition, XPE foam material and IXPE foam material also have thermal insulation, heat insulation, shock absorption and other properties. XPE foaming machine line will be used in the foaming process of XPE materials. XPE foaming machine line includes at least three major units: special granulator for XPE foam and IXPE foam, special sheet extruder for XPE foam and IXPE foam, special foaming furnace for XPE foam and IXPE foam.

-

06-02 2023

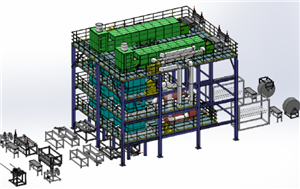

3 IXPE gas foaming machine lines exported abroad are being assembled in our factory

This IXPE foaming production line includes the following components: unwinding machine, special feeder for IXPE foaming machine, horizontal foaming furnace, vertical foaming furnace, vacuum adsorption expansion mechanism for IXPE foaming machine, furnace mouth traction machine and five-roller cooling machine, A complete IXPE foaming unit such as a special sheet tractor for a foaming machine, a special winding machine for a foaming machine, etc.

-

03-09 2023

XPE foam machine production line customer return visit

Recently, the project manager of our company and his team paid a return visit to the customer of the XPE foaming furnace production line located in Jiangsu, China. In this return visit, we helped customers solve some problems encountered when using the horizontal XPE foaming machine; shared our new technology in foaming machine and foaming process; exchanged the status quo of XPE foaming industry at home and abroad; the development trend of XPE foam and IXPE foam industry is analyzed.

-

02-13 2023

Working with Excellent domestic foaming sencondary equipment suppliers

Qinding is a manufacturer specializing in the production of XPE foam machine and IXPE foaming machine, and is also the best supplier of whole solution for fully automatic XPE making foaming machine and IXPE foaming production line in China. More than ten years of experience in developing and manufacturing, We are able to make the solutions for each individual project, and constantly improving and optimizing XPE faoming and IXPE foaming process.

-

06-09 2022

Introduction to the properties and applications of XPE foam and IXPE foam materials

In the production process of XPE foam and IXPE foam materials, according to different application requirements, various preparations can be added to give the product various unique properties, such as: flame retardant, weather resistance, aging resistance, chemical resistance, mildew resistance Wait. According to different additives, XPE foam and IXPE foam products can be divided into antibacterial enhanced type, flame retardant type, conductive type, weather-resistant type, anti-ultraviolet type, etc. Antibacterial enhanced IXPE is suitable for high-end series products of green home life; flame-retardant XPE foam and IXPE foam are suitable for automobiles, construction and home decoration, etc.; conductive IXPE foam is suitable for electronic appliances, precision packaging and other applications; weather-resistant and anti-ultraviolet XPE foam And IXPE foam is suitable for outdoor, water and other places. In addition, XPE foam and IXPE foam with other special properties can also be produced according to customer needs.

-

03-24 2022

Ningbo Qinding Material Technology Co., Ltd. has won 2 software copyrights from the State Intellectual Property Office of China

At the beginning of 2022, the two software copyrights that Qinding Company applied for again were authorized by the State Intellectual Property Office. So far, Ningbo Qinding Material Technology Co., Ltd. has owned 3 invention patents, 11 utility model patents, and 6 software copyright patents! Qinding company is a professional XPE/XLPE/IXPE/IXPP foaming machine and service provider led by 2 senior engineers and a number of engineers who have been engaged in XPE/XLPE/IXPE/IXPP foaming for more than 10 years. Qinding company has many honors such as Zhejiang Science and Technology Small and Medium-sized Enterprises, National High-tech Enterprises and so on. Facing the world, our company is a highly professional enterprise serving the XPE/XLPE/IXPE/IXPP foaming industry! It can provide global XPE/IXPE/XLPE/IXPP foaming enterprises with a full range of services from plant layout, IXPE/XLPE foaming machine selection, technical formula, engineering process, production training, and large-scale production.

-

03-05 2022

Remember service engineer of Qinding Company overcomes all difficulties to reach the Russian customer's on-site service for XLPE/IXPE foaming machine

No matter how the world epidemic is raging, Qin Ding people's enthusiasm for service cannot be stopped ——Remember that the after-sales service engineer of Qinding Company overcomes all difficulties to reach the Russian customer's on-site service for XLPE/IXPE foaming machine lines At the beginning of February 2022, when the bell of the Spring Festival just rang and all Chinese people were still immersed in the festive atmosphere of the Chinese New Year, the after-sales service engineers of Qinding Company had already packed their bags and taken all epidemic prevention measures. Departing from the site of Russian customers, we will provide installation and commissioning services for XPE/XLPE/IXPE foaming machine lines.

-

01-11 2022

The new XPE IXPE foam machine factory of Qinding Company is about to be completed and will be put into use after the Chinese New Year

The factory is designed and constructed in accordance with modern management, and is made of steel structure. Office and manufacturing are integrated, which is more conducive to personnel communication and production coordination. Due to the large footprint of our XLPE IXPE foaming machine lines, the workshop is designed and built to the largest size possible.

-

01-07 2022

The fourth set of IXPE foaming furnace machine ordered by an old customer of our company in southern China is being installed in advance

This is an IXPE manufacturing company located in southern China, and has signed a supply contract for three sets of IXPE foaming furnace production lines with our company. This is the fourth set of IXPE foaming furnace machine we have cooperated with. It was originally planned to be installed in mid-February 2022. However, due to the continuous increase in customer orders, the previous three sets of IXPE foaming operations can no longer meet the production needs. Under the premise of full communication between our two parties, our company is anxious to the customer's urgency, re-adjust the production order, and appoint a dedicated person to rush to make this set of IXPE Foaming furnace machine. Recently, the installation of the main body of this IXPE foaming furnace at the customer site has come to an end.

-

12-02 2021

Application of XPE IXPE foam material in air-conditioning insulation pipe

Air-conditioning cooling liquid copper pipes need to be insulated. The main materials of air-conditioning insulation pipes usually used are EPDM, NBR, EPE, XPE, IXPE and other rubber and plastic foam materials. EPDM and NBR are foam rubbers with open-cell structure, high water absorption rate, and easy to age outdoors, but the material cost is low and it is widely used. EPE is a foamed plastic tube that can be directly molded, but due to its open-cell structure, it also has the disadvantages of high water absorption and easy aging. Because it can be directly formed into a tube, the production cost is low, and the installation is convenient, so it is used more in areas with less developed economy. XPE and IXPE are closed-cell foamed plastics, which are much higher than other materials in terms of thermal insulation and comprehensive performance. XPE foam and IXPE foam are cross-linked foam materials with high cross-linking degree, excellent weather resistance and corrosion resistance. Long service life outdoors. However, when a single XPE or IXPE foam material is used to make pipes, it is more difficult to manufacture because of the greater internal stress of the plastic. Because of the high cost, it is usually used in high-demand occasions.