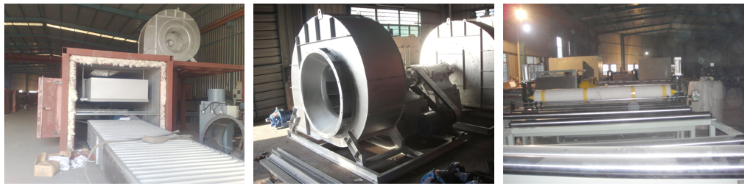

Another set of XPE foaming machine of Qin Ding Company is about to be completed

Recently, a leading XPE product company located in Guangdong, China, in order to meet the rapidly growing business, the XPE foaming machine produced by our company, which was purchased recently, is about to complete factory production and enter the delivery stage.

The XPE/IXPE foaming machine division is one of the three divisions of Qin Ding Company, and it has 2 production bases. The main products are XPE foaming machine (Horizontal production line), IXPE foaming machine (Vertical production line), XPE/IXPE foam sheet extruder, XPS foam product line etc. We have advanced Crosslink Foam technology and craftsmanship and a professional PE Tech Foam team, which can provide a variety of advanced project solutions for customers to choose from.

Qinding Company's Service Commitment

The fully automatic XPE/IXPE foam production line produced by Qin Ding has passed the EU CE certification and has many customers in the domestic and international industries. We provide not only equipment, but also high-quality services. Whether it is pre-sales consultation, after-sales service, or technical formula, personnel training, and large-scale production, we can give you a satisfactory answer.

1. Service tenet:

1.1 Quality policy: provide customers with more reliable products and services;

1.2 Mission: Make customers feel at ease about buying and using products;

1.3 Service commitment: 100% implementation of the contract, providing fast and excellent after-sales service.

2. Pre-sale service:

2.1 Provide customers with consulting services on the structure, configuration, input-output and other matters of the IXPE production line (XPE production line), and provide detailed production line configuration plans according to the customer's target market;

2.2 Assist customers to make the most reasonable layout according to the actual situation of the IXPE production line workshop.

3. In-sale service

3.1 After the contract is signed, Qin Ding will design the equipment basic drawing according to the actual construction situation of the customer's workshop (the customer is responsible for the basic construction), and assist the customer in the layout of cooling water, gas, electricity, and compressed air;

3.2 Installation: After the production line is shipped, Qin Ding will arrange project managers, professional mechanical and electrical engineers to arrive at the customer site to guide the installation;

3.3 Commissioning: After the installation of the production line is completed, Qin Ding will arrange for experienced commissioning engineers to arrive at the site for commissioning and explain the operating procedures on site.

4. Personnel training:

4.1 Process training: The training will be carried out at the customer's site, and will be completed by the Qinding company debugger and the customer's company operator. The training time is 2 weeks, so that the relevant operators are able to use the equipment to achieve the expected results;

4.2 Formulation delivery: Qin Ding’s project manager delivers to the technical personnel designated by the customer the conventional formula, the principle of formula adjustment, the role and proportion of the raw materials and auxiliary materials, the causes and solutions of problems during production, and the combination of process and formula. data.

5. After-sales service:

5.1 After-sales consultation: The email sent by the customer due to various problems during normal use will be responded to within 1 working day;

5.2 The entire equipment is guaranteed for one year, and it is responsible for maintenance outside the period. Only the material cost is charged for maintenance;

5.3 Visit customers from time to time to track product quality and ensure the safe operation of equipment.