Three methods of cross-linking and foaming of polyethylene under normal pressure

The molding methods of polyethylene foam include extrusion, injection, molding, orientation and other methods. Among them, the extrusion method is divided into direct extrusion foaming and cross-linking foaming after extrusion. After extrusion, cross-linked foaming can be divided into chemical cross-linked foaming, physical cross-linked foaming and mixed cross-linked foaming.

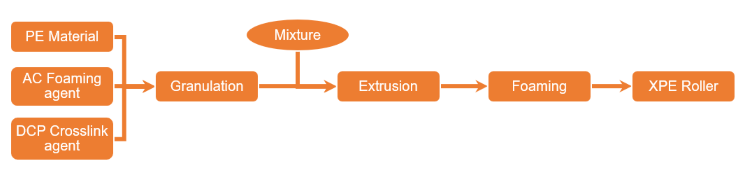

1. Normal pressure chemical cross-linking foaming method:

After extruding with a chemical foaming agent, the process of normal pressure crosslinking and foaming is to mix the chemical foaming agent, the chemical crosslinking agent (the decomposition temperature is lower than the foaming agent) and the resin, and then extrude them. Heating first decomposes the cross-linking agent and cross-links the resin. Then the blowing agent decomposes and releases gas in a high-temperature furnace to make foam plastic. The main foaming machines required by the foaming method include: a pelletizing unit, a sheet extruding unit, and a foaming furnace unit.

Atmospheric chemical cross-linking foaming method, there are two ways to heat the tempered and extruded sheet: one is to heat it at a certain temperature for an appropriate time to decompose the cross-linking agent (the foaming agent does not start) Decomposition), the resin is cross-linked, and then the temperature is increased to decompose the blowing agent. This method is called a two-stage heating method. The other is to raise the temperature from the air temperature to the temperature above the decomposition temperature of the blowing agent at a time, so that the crosslinking and foaming can proceed simultaneously. This method is called a one-stage heating method. In the one-stage heating method, part of the cross-linking agent decomposes before the foaming agent. This principle remains the same, but the amount of cross-linking must be slightly larger, so the degree of cross-linking is increased, and the heat resistance and strength of the foam are improved.

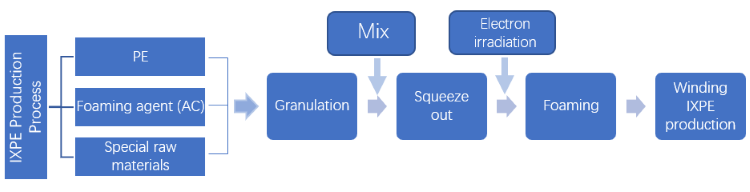

2. Electronic radiation cross-linking foaming method:

The foaming method does not use a chemical crosslinking agent, but uses electron beam radiation to crosslink. At this time, polyethylene and foaming agent are mixed at a temperature lower than the decomposition temperature of the foaming agent, and extruded into a film or sheet at the same temperature with an extruder, and then irradiated with a dose of 0.1-20 Mev. Then heat to above the decomposition temperature of the blowing agent to decompose the blowing agent to release gas and make foam plastic. Such as radiation cross-linking under heating, the cross-linking efficiency can be improved. In addition, there are also radiation cross-linking in an oxygen-containing gas, and then heating and foaming under reduced pressure. The main foaming machines required by the foaming method include: a pelletizing unit, a sheet extruding unit, an electronic accelerator unit, and a foaming furnace unit.

3. Hybrid cross-linking foaming method:

The foaming method is a combination of chemical cross-linking agent cross-linking and electron radiation cross-linking, which is to extrude the formed expandable material containing chemical foaming agent and chemical cross-linking agent into a sheet with an extruder The material is then irradiated with electron rays to make it slightly cross-linked. Then heating decomposes the crosslinking agent and foaming separately. This method can solve the problem of the sheet sticking to the steel mesh when cross-linked with a chemical cross-linking agent, and can also make up for the shortcomings of the electron beam cross-linking method, and can produce thicker foam materials.