-

06-09 2022

Introduction to the properties and applications of XPE foam and IXPE foam materials

In the production process of XPE foam and IXPE foam materials, according to different application requirements, various preparations can be added to give the product various unique properties, such as: flame retardant, weather resistance, aging resistance, chemical resistance, mildew resistance Wait. According to different additives, XPE foam and IXPE foam products can be divided into antibacterial enhanced type, flame retardant type, conductive type, weather-resistant type, anti-ultraviolet type, etc. Antibacterial enhanced IXPE is suitable for high-end series products of green home life; flame-retardant XPE foam and IXPE foam are suitable for automobiles, construction and home decoration, etc.; conductive IXPE foam is suitable for electronic appliances, precision packaging and other applications; weather-resistant and anti-ultraviolet XPE foam And IXPE foam is suitable for outdoor, water and other places. In addition, XPE foam and IXPE foam with other special properties can also be produced according to customer needs.

-

12-02 2021

Application of XPE IXPE foam material in air-conditioning insulation pipe

Air-conditioning cooling liquid copper pipes need to be insulated. The main materials of air-conditioning insulation pipes usually used are EPDM, NBR, EPE, XPE, IXPE and other rubber and plastic foam materials. EPDM and NBR are foam rubbers with open-cell structure, high water absorption rate, and easy to age outdoors, but the material cost is low and it is widely used. EPE is a foamed plastic tube that can be directly molded, but due to its open-cell structure, it also has the disadvantages of high water absorption and easy aging. Because it can be directly formed into a tube, the production cost is low, and the installation is convenient, so it is used more in areas with less developed economy. XPE and IXPE are closed-cell foamed plastics, which are much higher than other materials in terms of thermal insulation and comprehensive performance. XPE foam and IXPE foam are cross-linked foam materials with high cross-linking degree, excellent weather resistance and corrosion resistance. Long service life outdoors. However, when a single XPE or IXPE foam material is used to make pipes, it is more difficult to manufacture because of the greater internal stress of the plastic. Because of the high cost, it is usually used in high-demand occasions.

-

11-07 2021

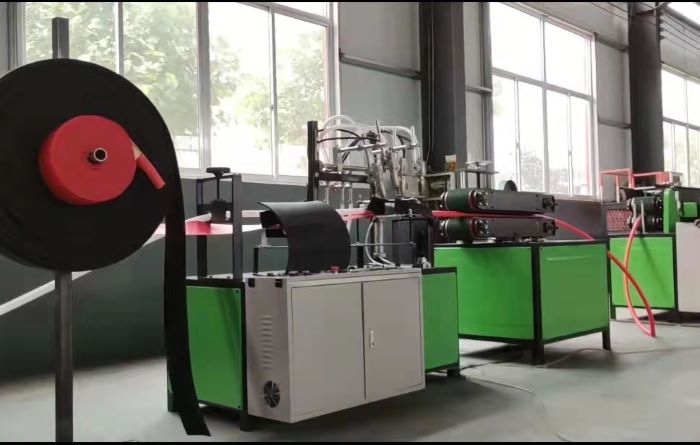

Application of IXPE foam material on SPC floor mat

IXPE foam material is a material with high technical requirements. It has high requirements on product formula, production process, machine equipment configuration and so on. Manufacturers need to customize different product formulas and production processes according to the needs of downstream users. Qin Ding has a large number of customers in this industry and has accumulated rich experience. It can provide different equipment according to the different markets targeted by customers, and can provide customers with a full range of materials, technical formulas, production processes, and secondary processing. And we can provide directional services.

-

07-26 2021

Application details of IXPE foam material and its composite products in automotive products

IXPE foam material has the following excellent physical properties: Flame retardant: The IXPE foaming products can reach FMVSS302 standard, UL standard, HB, V-2, V-1, V-0 (HB UL94 plastic flame retardant grade inspection method). Environmental protection: tested by SGS, the world's most authoritative organization, 100% of the IXPE foaming products have passed the EU ROSH environmental protection directive, free of peculiar smell and toxic substances. Heat insulation: IXPE foam products independent cell structure, no air circulation, thermal conductivity ≤0.04W/m∙k. Sound insulation: 100% airtight chamber, effectively reducing the sound intensity, excellent sound insulation, meeting STC-73, IIC-72 standards Waterproof: water absorption rate is lower than 0.02g/cm2 Aging resistance: After being modified by electron irradiation, IXPE foaming products have good weather resistance and chemical resistance, and the aging time is more than 15 years.

-

07-24 2021

Three methods of cross-linking and foaming of polyethylene under normal pressure

The molding methods of polyethylene foam include extrusion, injection, molding, orientation and other methods. Among them, the extrusion method is divided into direct extrusion foaming and cross-linking foaming after extrusion. After extrusion, cross-linked foaming can be divided into chemical cross-linked foaming, physical cross-linked foaming and mixed cross-linked foaming.

-

07-09 2021

IXPE foam material has broad development prospects

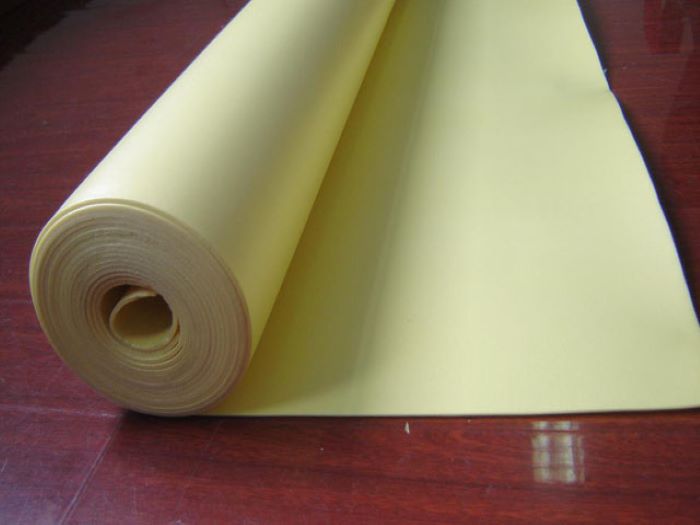

The full name of IXPE foam material is electron radiation cross-linked polyethylene foam material. It is based on LDPE (low-density high-pressure polyethylene), ADC foaming agent and color masterbatch as the main raw materials, with other auxiliary materials, after granulation and extrusion molding processes, the use of high-energy electron beams generated by industrial electron accelerators to extrude The formed mother film is irradiated to build a chain bridge between the molecules, and then foamed at a high temperature to form an independent closed-cell foam material. Finally, the material can be processed into the final foam product after punching, printing, thickening and other back-end processing procedures.