-

04-14 2024

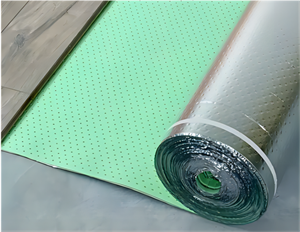

Application of IXPE foam material on SPC floor mats

Qinding Company has been deeply involved in the SPC-specific IXPE foaming machine industry for many years. The company is led by 2 senior engineers who have been in the industry for more than 20 years; more than 70 professional technical and manufacturing teams; with a professional production plant of 18,000 sqm for IXPE foaming machine line; and has provided more than 100 IXPE foaming machine production lines for the SPC-specific IXPE foaming industry at home and abroad. Recently, our company's process engineers have developed a set of effective formula for IXPE foam products specifically for the SPC industry. After large-scale production and application, this IXPE foaming formula can not only achieve effective anti-mildew and anti-bacterial properties, but also increase post-corona resistance. The glue coating effect can also extend the timeliness after corona. Our company is applying for domestic and international patents for this IXPE foaming formula, and I believe there will be good news soon.

-

02-29 2024

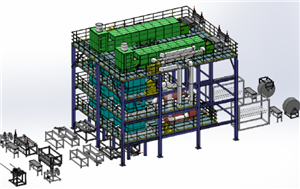

Qinding Company's new gas foaming machine line is entering the commissioning stage in a central Chinese city

This IXPE foaming production line includes the following components: unwinding machine, special feeder for IXPE foaming machine, horizontal foaming furnace, vertical foaming furnace, vacuum adsorption expansion mechanism for IXPE foaming machine, furnace mouth traction machine and five-roller cooling machine, A complete IXPE foaming unit such as a special sheet tractor for a foaming machine, a special winding machine for a foaming machine, etc.

-

12-29 2023

Office address relocation announcement in Ningbo city

Qin Ding Company serves the XPE/IXPE foam and Crosslink foam industries, and has 2 foaming machine manufacturing plants and 1 foaming mat manufacturing plant. The Floating mat, PE Tech Foam Coil, Crosslink Foam Floating Pad and Crosslink Foam Children Climbing Mat products of the company's Sunhigh brand have been sold on Amazon. The IXPE foam machine and XPE foam machine produced by the head office are sold at home and abroad. Qin Ding has advanced Crosslink Foam technology and craftsmanship and a professional PE Tech Foam team, which can provide a variety of advanced project solutions for customers to choose from. Welcome new and old customers to call or write to negotiate.

-

12-04 2023

The second phase of the Xiangshan factory of Qinding Company for IXPE foaming machine has started construction

Recently, the second phase of the Xiangshan Factory project has completed the main construction and is about to enter the plant capping stage. This project is specially designed and constructed to meet the requirements of the production, manufacturing and manufacturing of Qinding Company's large-scale IXPE foaming furnace production line. The total height of the factory building is 18.35m, with a single span of 8m. Each span of the workshop will be equipped with two 32-ton cranes with a maximum lifting height of 13.5m. After the construction is completed, it will be able to start production of 4 IXPE foaming furnace production lines and 3 XPE foaming production lines at the same time; it will have an annual production capacity of 32 XPE foaming production lines or IXPE foaming production lines.

-

11-12 2023

The 3500mm XPE foam production machine ordered by foreign customer has entered the assembly stage in our factory

Recently, the ultra-wide XPE foam production machine ordered by foreign company from Qin Ding Company has begun to enter the assembly stage. This XPE foaming production machine is a horizontal foaming production line. The target XPE coil specifications are a maximum thickness of 15mm and a maximum width of 3000mm. To this end, the effective width of the foaming furnace designed by our company is 3500mm and the length of the furnace body is 25M. This foaming furnace can produce products with a maximum thickness of 20mm, a maximum width of 3200mm, and a maximum output of 5.5~6T/24h.

-

10-25 2023

IXPE foaming machine lines produced by Qin Ding company are packed and shipped abroad

This IXPE foaming production line includes the following components: unwinding machine, special feeder for IXPE foaming machine, horizontal foaming furnace, vertical foaming furnace, vacuum adsorption expansion mechanism for IXPE foaming machine, furnace mouth traction machine and five-roller cooling machine, A complete IXPE foaming unit such as a special sheet tractor for a foaming machine, a special winding machine for a foaming machine, etc.

-

09-05 2023

Qin Ding engineers commissioned IXPE foam production machine abroad, and returned visit to old customers

In mid-August 2023, HNREY, the project manager of our company's IXPE foam production machine line, led the commissioning engineers to go abroad to debug a set of IXPE foaming machine line.

-

07-21 2023

Development and application of XPE foam material in XPE floating mat

The application of the floating blanket on the water utilizes the characteristics of closed-cell foaming, hydrophobicity and light weight of XPE foam material and IXPE foam material. In addition, XPE foam material and IXPE foam material also have thermal insulation, heat insulation, shock absorption and other properties. XPE foaming machine line will be used in the foaming process of XPE materials. XPE foaming machine line includes at least three major units: special granulator for XPE foam and IXPE foam, special sheet extruder for XPE foam and IXPE foam, special foaming furnace for XPE foam and IXPE foam.

-

06-02 2023

3 IXPE gas foaming machine lines exported abroad are being assembled in our factory

This IXPE foaming production line includes the following components: unwinding machine, special feeder for IXPE foaming machine, horizontal foaming furnace, vertical foaming furnace, vacuum adsorption expansion mechanism for IXPE foaming machine, furnace mouth traction machine and five-roller cooling machine, A complete IXPE foaming unit such as a special sheet tractor for a foaming machine, a special winding machine for a foaming machine, etc.

-

03-09 2023

XPE foam machine production line customer return visit

Recently, the project manager of our company and his team paid a return visit to the customer of the XPE foaming furnace production line located in Jiangsu, China. In this return visit, we helped customers solve some problems encountered when using the horizontal XPE foaming machine; shared our new technology in foaming machine and foaming process; exchanged the status quo of XPE foaming industry at home and abroad; the development trend of XPE foam and IXPE foam industry is analyzed.