-

06-02 2023

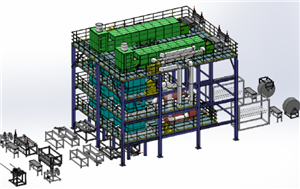

3 IXPE gas foaming machine lines exported abroad are being assembled in our factory

This IXPE foaming production line includes the following components: unwinding machine, special feeder for IXPE foaming machine, horizontal foaming furnace, vertical foaming furnace, vacuum adsorption expansion mechanism for IXPE foaming machine, furnace mouth traction machine and five-roller cooling machine, A complete IXPE foaming unit such as a special sheet tractor for a foaming machine, a special winding machine for a foaming machine, etc.

-

02-13 2023

Working with Excellent domestic foaming sencondary equipment suppliers

Qinding is a manufacturer specializing in the production of XPE foam machine and IXPE foaming machine, and is also the best supplier of whole solution for fully automatic XPE making foaming machine and IXPE foaming production line in China. More than ten years of experience in developing and manufacturing, We are able to make the solutions for each individual project, and constantly improving and optimizing XPE faoming and IXPE foaming process.

-

01-28 2023

Another set of complete XPE foaming machine line manufactured by Qinding Company was exported abroad

The XPE foam machine production line exported by Qinding Company this time mainly produces flame-retardant XPE foam coils (FR XPE foam material) with a width of 1800mm and a thickness of 22mm. The ultimate application products of XPE materials produced by customers are products in the green building industry. The XPE foaming machine production line exported by Qinding Company this time includes granulation unit of XPE foaming machine, auto mixing and feeding unit of XPE foaming machine, sheet extrusion unit of XPE foaming machine, and foaming furnace unit of XPE foaming machine.

-

12-05 2022

Another set of XPE foam machine manufactured by Qinding Company was delivered to customer in Linyi China

The XPE foaming machine line installed in Linyi adopts the traditional XPE foam production process. The whole set of XPE foaming machine line includes granulation unit, mother sheet extruder unit and horizontal XPE foaming furnace unit. It can produce XPE foam products with single layer thickness of 2~25mm and width of 1800mm. In addition, this project is equipped with a complex machine unit. Through thermal lamination, the thickness can be increased to a max thickness of 100mm ultra-thick XPE.

-

10-09 2022

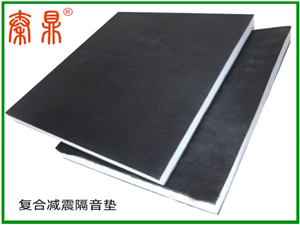

Application of XPE foam and IXPE foam material on floating floor mat

The sound insulation material in the floating floor slab is XPE IXPE foam material, and its production process is as follows: 1. According to a certain ratio of raw materials such as PE, masterbatch particles are produced by the kneading and granulating unit of the XPE IXPE Foam machine line. 2. After mixing the PE and the master batch produced in the first step according to another formula, the master sheet is produced by the master sheet extruding unit of the XPE IXPE Foam machine line. If DCP is added in this step, XPE foam material is produced, and the third step can be directly skipped into the foaming machine for foaming process. 3. The master sheet produced in the second step is subjected to the cross-linking process through the irradiation unit of the XPE IXPE Foam machine line. 4. The DCP-added master sheet or the irradiated master sheet is foamed through the foaming machine unit of the XPE IXPE Foam machine line to obtain XPE Foam or IXPE Foam material. 5. Pass the thin XPE IXPE foam material through the secondary processing unit of the XPE IXPE Foam machine line for the thickening process. Usually, a layer of 4~5mm black XPE IXPE foam material is sandwiched between 2 layers of 3mm black XPE IXPE foam material, so as to obtain a composite material with a thickness of 10~11mm. Through the above 5 steps, the sound insulation material for floating floor is completed.

-

05-29 2022

Ningbo Qinding Material Technology Co., Ltd. participated in the 2022 Dragon Boat Race of the Hunan Chamber of Commerce

Ningbo Qinding Material Technology Co., Ltd., one of the members of Hunan Chamber of Commerce, participated in the 2022 Dragon Boat Race of the Hunan Chamber of Commerce. Qin Ding Company serves the XPE IXPE foam and Crosslink foam industries, and has 2 foaming machine manufacturing bases and 1 foaming mat manufacturing plant. The Floating mat, PE Tech Foam Coil, Crosslink Foam Floating Pad and Crosslink Foam Children Climbing Mat products of the company's Sunhigh brand have been sold on Amazon. The IXPE foam machine and XPE foam machine produced by the head office are sold at home and abroad. Qin Ding has advanced Crosslink Foam technology and craftsmanship and a professional PE Tech Foam team, which can provide a variety of advanced project solutions for customers to choose from. Welcome new and old customers to call or write to negotiate.

-

01-11 2022

The new XPE IXPE foam machine factory of Qinding Company is about to be completed and will be put into use after the Chinese New Year

The factory is designed and constructed in accordance with modern management, and is made of steel structure. Office and manufacturing are integrated, which is more conducive to personnel communication and production coordination. Due to the large footprint of our XLPE IXPE foaming machine lines, the workshop is designed and built to the largest size possible.

-

11-07 2021

Application of IXPE foam material on SPC floor mat

IXPE foam material is a material with high technical requirements. It has high requirements on product formula, production process, machine equipment configuration and so on. Manufacturers need to customize different product formulas and production processes according to the needs of downstream users. Qin Ding has a large number of customers in this industry and has accumulated rich experience. It can provide different equipment according to the different markets targeted by customers, and can provide customers with a full range of materials, technical formulas, production processes, and secondary processing. And we can provide directional services.

-

08-15 2021

The IXPE gas heating foam machine ordered by a large foreign company from Qin Ding Company was shipped

From August 1st to 2nd, 2021, the IXPE gas heating foam machine signed by a large foreign enterprise company and Qin Ding Company was delivered. A total of 8 containers are shipped this time. The entire production line includes a discharger, a storage device, a tractor, a gas-heated horizontal foaming machine, a gas-heated vertical foaming machine, an exhaust gas recovery integrated heating unit, and a vacuum expansion unit. , Five-roller cooling unit, surface treatment unit, correction unit, trimming traction unit, winding unit and corresponding frame.

-

07-26 2021

Application details of IXPE foam material and its composite products in automotive products

IXPE foam material has the following excellent physical properties: Flame retardant: The IXPE foaming products can reach FMVSS302 standard, UL standard, HB, V-2, V-1, V-0 (HB UL94 plastic flame retardant grade inspection method). Environmental protection: tested by SGS, the world's most authoritative organization, 100% of the IXPE foaming products have passed the EU ROSH environmental protection directive, free of peculiar smell and toxic substances. Heat insulation: IXPE foam products independent cell structure, no air circulation, thermal conductivity ≤0.04W/m∙k. Sound insulation: 100% airtight chamber, effectively reducing the sound intensity, excellent sound insulation, meeting STC-73, IIC-72 standards Waterproof: water absorption rate is lower than 0.02g/cm2 Aging resistance: After being modified by electron irradiation, IXPE foaming products have good weather resistance and chemical resistance, and the aging time is more than 15 years.