1 set of electric IXPE vertical foaming furnace produced by our company is being installed in an IXPE factory in southern China

Recently, a set of IXPE electric heating vertical foaming furnace produced by our company was sent to the customer's factory and entered a 15-day installation cycle.

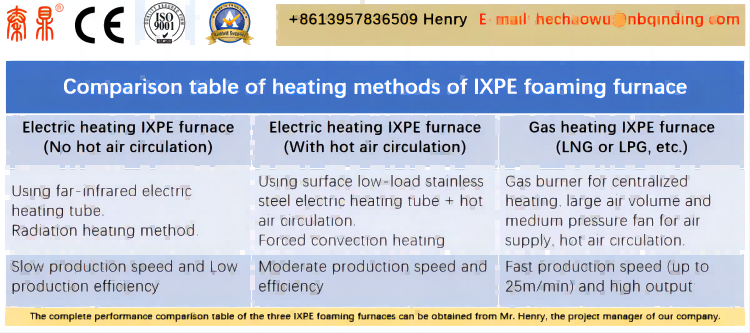

This set of IXPE foaming furnace adopts the structure of horizontal furnace + vertical furnace. It uses an all-electric heating mode with a total heating power of 175kW. This type of electrically heated IXPE foaming furnace technology is very mature and is also one of the best in China. A very common electric heating IXPE foaming furnace. In order to fully cover the IXPE foaming industry, as for electric heating IXPE foaming furnaces, our company can also provide two furnace types: hot air circulation type and non-hot air circulation type. At the same time, our company also has gas-heated IXPE foaming furnaces for IXPE factories to choose from. IXPE production customers can choose any IXPE foaming furnace that suits them based on their factory site, equipment investment budget, production and operation costs, output requirements, etc.

The factory Chairman -Mr. Chen’s factory is the only IXPE foam product manufacturer in this geographical area. It mainly provides high-quality IXPE foam products to the leisure sports industry and the construction industry. Currently, Mr. Chen has many orders for IXPE foam rolls and his business is very busy. In order not to affect the normal IXPE foaming production of the factory, this installation took into account the installation conditions and construction environment on site, and in order to shorten the installation time, we divided the vertical section of the IXPE foaming furnace into two sections in the factory, and the supporting chassis was Monolithic. After arriving at Mr. Chen's factory, first assemble the vertical section of the IXPE foaming furnace. Then, the upper end of the vertical section of the entire IXPE foaming furnace is lifted with an electric hoist. The bottom end is lifted with a forklift, and the supporting chassis is placed into the IXPE foaming furnace. the bottom. In this way, the vertical section of the IXPE foaming furnace is in place, and the installation speed is very fast.

After the installation of this set of IXPE vertical foaming furnace is completed, Mr. Chen's factory will have the production capacity of IXPE foam rolls with IXPE product width up to 2500mm and the total annual output of 12 million square meters. However, the market demand is still huge. This is only the first step for Mr. Chen to lay out the development of IXPE foam industry. Next year, he will purchase multiple sets of IXPE vertical foaming production lines, specially used to produce ultra-thin IXPE foam rolls.

We hope that our customers' business will become more and more prosperous.