Application details of XPE foam and IXPE foam material in lawn mats

Because XPE foam and IXPE foam have the properties of shock absorption, water resistance, and resilience, they are widely used, and their application on artificial turf mats is worth recommending.

1. Production of XPE coils

XPE foaming machine (main machine including pelletizing unit, master chip extruding unit, XPE foaming furnace unit) is used to produce XPE coils. The thickness of this kind of coil is generally 8~12mm, the width is mostly 1.5m, the length of a single coil is generally 72m, and the XPE coil has a magnification of 30~35 times. It requires fine foam cells and good resilience. The colors are mainly green XPE foam and milky white XPE foam, some of them will use natural XPE foam, and black XPE foam will be used less.http://www.nbqinding.com/product/xpe-horizontal-foaming-furnace

2. XPE coil punching

The produced XPE foam coils are transferred to the secondary processing workshop for punching. The purpose of punching is to prevent water from accumulating on the lawn mat on rainy days, and at the same time increase the softness and comfort of the overall lawn mat. The punching shape is mainly "()", there are also rectangular holes, round holes, etc. The hole size is generally: width 3~5mm, length 20~30mm. Punching equipment technology: unwinding-correction-pulse punching machine-correction-rewinding.

3. Site construction

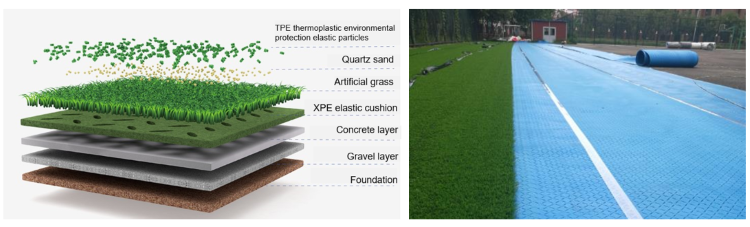

Lay layer by layer in the following way:

Foundation-gravel layer-concrete layer-XPE foam punching coil-artificial turf mat-quartz sand-TPR elastic particles.

After laying the XPE foam coil, use a single-sided tape to glue the seams firmly.