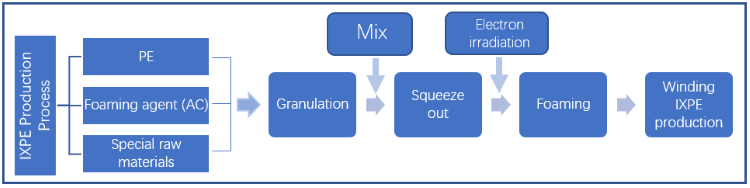

IXPE foamed coil production process introduction

IXPE foam products are more and more widely used due to their excellent physical properties. IXPE foam products, as a substitute for XPE foam and EPE foam, will also be a market trend.

The production process of IXPE foaming is as follows:

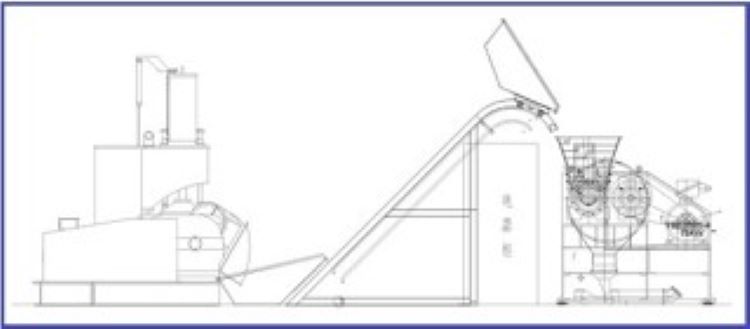

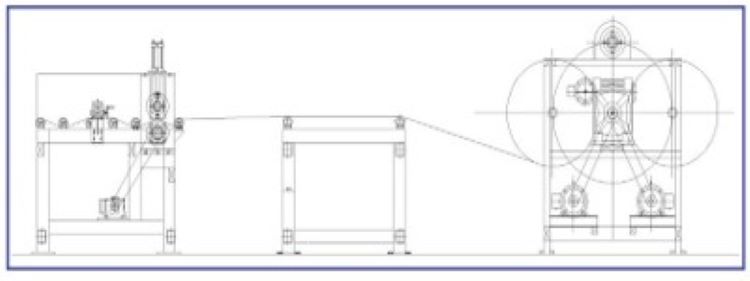

1.Granulation

Polyethylene resin (PE), foaming agent (AC) and other auxiliary materials are mixed into particles with different functions after internal mixing, melting and hot granulation.The granulation unit is an indispensable machine in the IXPE foaming machine and XPE foaming machine.

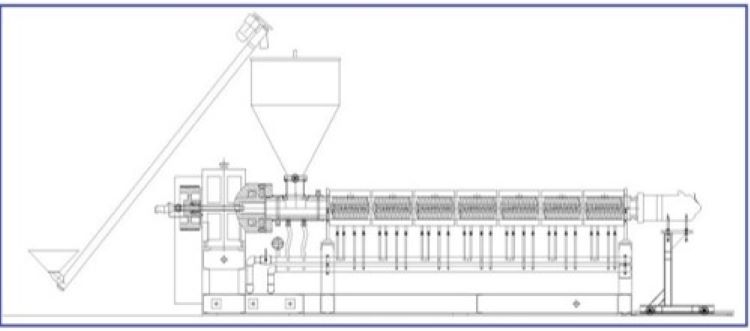

2.Extrusion

The mixed particles after internal mixing were mixed again according to the formula proportion, and then extruded and cooled to form sheet after high temperature melting. Extrusion temperature is 90-210℃, screw speed is 10-50r/min.

3. Irradiation Crosslink

Irradiation on the sheet through electron accelerator , the original macromolecular polymer is dehydrogenated and combined to form a network structure, which greatly increases the adhesion between molecules, thus enhancing the thermal stability, strength, corrosion resistance and other physical properties of the material.

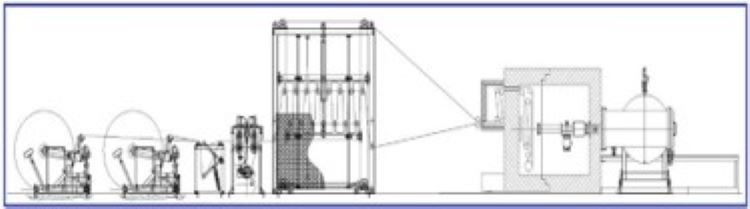

4.Foaming

Foaming in a high temperature furnace. The furnace body is horizontal heating + vertical heating, and the heat source can be electric heating or gas heating. After irradiation, the master piece decomposed at high temperature to form fine and closed bubbles, and stable IXPE foam was obtained.

5.Rolling and finished

After a series of processes, such as surface treatment, cooling, trimming and corona, IXPE coil is formed.

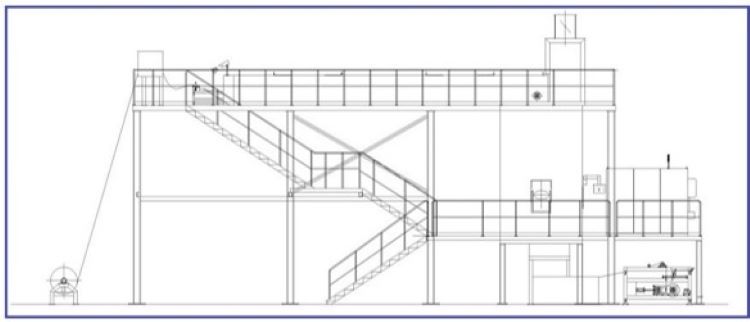

Total area of the production line is about 120m*5m*5m (the height of the foaming furnace need 10m, if heated by gas the height of workshop is at least 13m).

Of course, the production of IXPE foaming products is a sophisticated and complex process. Every link is indispensable and very important. If a perfect IXPE foaming product is to be produced, process control is very important. Qin Ding is a professional IXPE foaming machine provider. It has more than 10 years of first-line production experience and has accumulated rich experience. It can provide customers with unique help from raw material selection, site planning, equipment selection, formula and technology, and personnel training. .