Application of several flame retardants in IXPE foam and XPE foam products

XPE foam products and IXPE foam products are organic polyethylene foamed at high temperatures. They have excellent physical properties and are widely used. However, in the automotive industry and the construction and home decoration industry, both XPE foaming and IXPE foaming products need to be flame retardant. In the industry, there are two commonly used flame retardants: brominated flame retardants and aluminum hydride flame retardants.

1. Brominated flame retardants

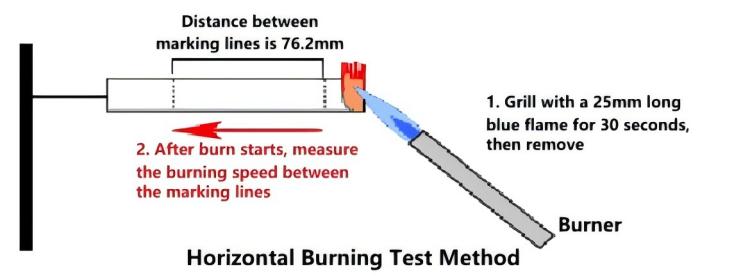

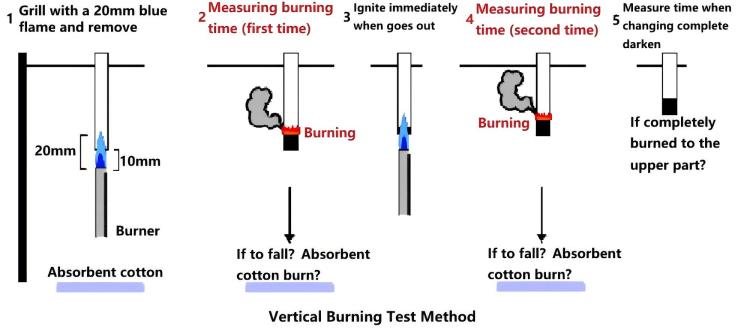

Brominated flame retardants are flame retardants that have been widely used in the industry for a long time. They have many advantages: good flame retardant effect; good compatibility with PE when IXPE foaming; easy operation when XPE foams; In the foaming formula system, the formula system is simple and easy to adjust. When the dosage is used appropriately, the flame retardant effect of XPE foam can reach V1 level, and the flame retardant effect of IXPE foam can reach HF-1≤30mm. (Test method: UL94-2013 Rev.9-2018 Section 12)

2. Aluminum hydride flame retardant

This is by far the best flame retardant among IXPE foam products and XPE foam products. Under the UL94-2013 experimental conditions, the flame retardant effect of XPE foaming can meet the requirements of V-0 level without obvious smoke. The flame retardant effect of IXPE foaming can reach HV-1 level. However, since aluminum hydride is an inorganic flame retardant and aluminum hydride is highly hygroscopic, it is difficult to adjust the formula system in both XPE foam and IXPE foaming formulations. Therefore, so far, only a few XPE foam and IXPE foam manufacturers have mastered better technology, or are still using this series of flame retardants in situations where XPE foam and IXPE foam products have higher requirements.

3. Halogen-free flame retardant

Halogen-free flame retardants include all halogen-free flame retardants or flame retardant systems. The main mechanism of action of halogen-free flame retardants is to form a porous carbon layer, which has the advantages of low smoke and non-toxicity. Generally, halogen-free flame retardants can be divided into inorganic flame retardants and organic flame retardants. Halogen-free flame retardant is an emerging flame retardant system in the XPE foaming and IXPE foaming industries in recent years. In the XPE foaming and IXPE foaming industries, the performance is between bromine-based flame retardants and aluminum hydride-based flame retardants. However, this flame retardant has the advantages of environmental protection, low smoke, and good flame retardant effect. In the formula system of XPE foam and IXPE foam, PE halogen-free flame retardant is commonly used, which is an organic flame retardant. Therefore, it has good compatibility with the mixture during the extrusion process of XPE foam and IXPE foam, and the formula system is also easy to adjust. Moreover, halogen-free flame retardants can meet both the EU WEEE and ROHS directives. Halogen-free flame retardants will definitely become the mainstream of XPE foam and IXPE foam flame retardant materials.

Today, with the rapid development of flame retardants, flame retardant technology is also rapidly achieving breakthroughs. In XPE foaming and IXPE foaming, surface modification technology, compound synergy technology, microencapsulation technology, ultrafine technology, cross-linking technology, macromolecule technology, etc. have been rapidly developed. In flame retardant , played a very important role in the fire protection industry.