-

02-29 2024

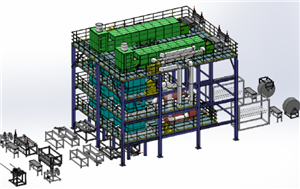

Qinding Company's new gas foaming machine line is entering the commissioning stage in a central Chinese city

This IXPE foaming production line includes the following components: unwinding machine, special feeder for IXPE foaming machine, horizontal foaming furnace, vertical foaming furnace, vacuum adsorption expansion mechanism for IXPE foaming machine, furnace mouth traction machine and five-roller cooling machine, A complete IXPE foaming unit such as a special sheet tractor for a foaming machine, a special winding machine for a foaming machine, etc.

-

12-29 2023

Office address relocation announcement in Ningbo city

Qin Ding Company serves the XPE/IXPE foam and Crosslink foam industries, and has 2 foaming machine manufacturing plants and 1 foaming mat manufacturing plant. The Floating mat, PE Tech Foam Coil, Crosslink Foam Floating Pad and Crosslink Foam Children Climbing Mat products of the company's Sunhigh brand have been sold on Amazon. The IXPE foam machine and XPE foam machine produced by the head office are sold at home and abroad. Qin Ding has advanced Crosslink Foam technology and craftsmanship and a professional PE Tech Foam team, which can provide a variety of advanced project solutions for customers to choose from. Welcome new and old customers to call or write to negotiate.

-

12-04 2023

The second phase of the Xiangshan factory of Qinding Company for IXPE foaming machine has started construction

Recently, the second phase of the Xiangshan Factory project has completed the main construction and is about to enter the plant capping stage. This project is specially designed and constructed to meet the requirements of the production, manufacturing and manufacturing of Qinding Company's large-scale IXPE foaming furnace production line. The total height of the factory building is 18.35m, with a single span of 8m. Each span of the workshop will be equipped with two 32-ton cranes with a maximum lifting height of 13.5m. After the construction is completed, it will be able to start production of 4 IXPE foaming furnace production lines and 3 XPE foaming production lines at the same time; it will have an annual production capacity of 32 XPE foaming production lines or IXPE foaming production lines.

-

11-12 2023

The 3500mm XPE foam production machine ordered by foreign customer has entered the assembly stage in our factory

Recently, the ultra-wide XPE foam production machine ordered by foreign company from Qin Ding Company has begun to enter the assembly stage. This XPE foaming production machine is a horizontal foaming production line. The target XPE coil specifications are a maximum thickness of 15mm and a maximum width of 3000mm. To this end, the effective width of the foaming furnace designed by our company is 3500mm and the length of the furnace body is 25M. This foaming furnace can produce products with a maximum thickness of 20mm, a maximum width of 3200mm, and a maximum output of 5.5~6T/24h.

-

10-25 2023

IXPE foaming machine lines produced by Qin Ding company are packed and shipped abroad

This IXPE foaming production line includes the following components: unwinding machine, special feeder for IXPE foaming machine, horizontal foaming furnace, vertical foaming furnace, vacuum adsorption expansion mechanism for IXPE foaming machine, furnace mouth traction machine and five-roller cooling machine, A complete IXPE foaming unit such as a special sheet tractor for a foaming machine, a special winding machine for a foaming machine, etc.

-

09-05 2023

Qin Ding engineers commissioned IXPE foam production machine abroad, and returned visit to old customers

In mid-August 2023, HNREY, the project manager of our company's IXPE foam production machine line, led the commissioning engineers to go abroad to debug a set of IXPE foaming machine line.

-

06-02 2023

3 IXPE gas foaming machine lines exported abroad are being assembled in our factory

This IXPE foaming production line includes the following components: unwinding machine, special feeder for IXPE foaming machine, horizontal foaming furnace, vertical foaming furnace, vacuum adsorption expansion mechanism for IXPE foaming machine, furnace mouth traction machine and five-roller cooling machine, A complete IXPE foaming unit such as a special sheet tractor for a foaming machine, a special winding machine for a foaming machine, etc.

-

12-05 2022

Another set of XPE foam machine manufactured by Qinding Company was delivered to customer in Linyi China

The XPE foaming machine line installed in Linyi adopts the traditional XPE foam production process. The whole set of XPE foaming machine line includes granulation unit, mother sheet extruder unit and horizontal XPE foaming furnace unit. It can produce XPE foam products with single layer thickness of 2~25mm and width of 1800mm. In addition, this project is equipped with a complex machine unit. Through thermal lamination, the thickness can be increased to a max thickness of 100mm ultra-thick XPE.

-

08-15 2021

The IXPE gas heating foam machine ordered by a large foreign company from Qin Ding Company was shipped

From August 1st to 2nd, 2021, the IXPE gas heating foam machine signed by a large foreign enterprise company and Qin Ding Company was delivered. A total of 8 containers are shipped this time. The entire production line includes a discharger, a storage device, a tractor, a gas-heated horizontal foaming machine, a gas-heated vertical foaming machine, an exhaust gas recovery integrated heating unit, and a vacuum expansion unit. , Five-roller cooling unit, surface treatment unit, correction unit, trimming traction unit, winding unit and corresponding frame.

-

07-24 2021

Three methods of cross-linking and foaming of polyethylene under normal pressure

The molding methods of polyethylene foam include extrusion, injection, molding, orientation and other methods. Among them, the extrusion method is divided into direct extrusion foaming and cross-linking foaming after extrusion. After extrusion, cross-linked foaming can be divided into chemical cross-linked foaming, physical cross-linked foaming and mixed cross-linked foaming.