-

08-15 2021

The IXPE gas heating foam machine ordered by a large foreign company from Qin Ding Company was shipped

From August 1st to 2nd, 2021, the IXPE gas heating foam machine signed by a large foreign enterprise company and Qin Ding Company was delivered. A total of 8 containers are shipped this time. The entire production line includes a discharger, a storage device, a tractor, a gas-heated horizontal foaming machine, a gas-heated vertical foaming machine, an exhaust gas recovery integrated heating unit, and a vacuum expansion unit. , Five-roller cooling unit, surface treatment unit, correction unit, trimming traction unit, winding unit and corresponding frame.

-

07-26 2021

Application details of IXPE foam material and its composite products in automotive products

IXPE foam material has the following excellent physical properties: Flame retardant: The IXPE foaming products can reach FMVSS302 standard, UL standard, HB, V-2, V-1, V-0 (HB UL94 plastic flame retardant grade inspection method). Environmental protection: tested by SGS, the world's most authoritative organization, 100% of the IXPE foaming products have passed the EU ROSH environmental protection directive, free of peculiar smell and toxic substances. Heat insulation: IXPE foam products independent cell structure, no air circulation, thermal conductivity ≤0.04W/m∙k. Sound insulation: 100% airtight chamber, effectively reducing the sound intensity, excellent sound insulation, meeting STC-73, IIC-72 standards Waterproof: water absorption rate is lower than 0.02g/cm2 Aging resistance: After being modified by electron irradiation, IXPE foaming products have good weather resistance and chemical resistance, and the aging time is more than 15 years.

-

07-24 2021

Three methods of cross-linking and foaming of polyethylene under normal pressure

The molding methods of polyethylene foam include extrusion, injection, molding, orientation and other methods. Among them, the extrusion method is divided into direct extrusion foaming and cross-linking foaming after extrusion. After extrusion, cross-linked foaming can be divided into chemical cross-linked foaming, physical cross-linked foaming and mixed cross-linked foaming.

-

07-09 2021

IXPE foam material has broad development prospects

The full name of IXPE foam material is electron radiation cross-linked polyethylene foam material. It is based on LDPE (low-density high-pressure polyethylene), ADC foaming agent and color masterbatch as the main raw materials, with other auxiliary materials, after granulation and extrusion molding processes, the use of high-energy electron beams generated by industrial electron accelerators to extrude The formed mother film is irradiated to build a chain bridge between the molecules, and then foamed at a high temperature to form an independent closed-cell foam material. Finally, the material can be processed into the final foam product after punching, printing, thickening and other back-end processing procedures.

-

06-30 2021

The IXPE foaming machine ordered by a large Korean company from Qin Ding Company is about to be completed

Recently, the gas-heated IXPE foaming machine purchased by a large Korean PVC plastic floor manufacturer from our company is about to complete the factory production stage and is expected to be shipped in early July.

-

06-16 2021

A set of XPE foam production line manufactured by Qin Ding Company was sent to India

After about 2 months of hard work, Qin Ding Company has made concerted efforts to complete a set of XPE foam production line that an Indian company ordered to our company. This batch of XPE foam production line cargo has been loaded into containers and entered the port on June 15. The ship will arrive at the port on June 22 and depart for the port of Mumbai, India on the 23rd. I wish this batch of goods can reach the port of Mumbai safely, and then our company will send professional engineers to install and debug.

-

06-10 2021

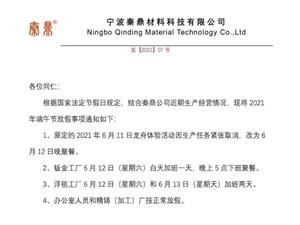

Holiday Notice for Dragon Boat Festival of Qin Ding Company

The XPE/IXPE foaming machine division is one of the three divisions of Qin Ding Company, and it has 2 production bases. The main products are XPE foaming machine (Horizontal production line), IXPE foaming machine (Vertical production line), XPE/IXPE foam sheet extruder, XPS foam product line etc. We have advanced Crosslink Foam technology and craftsmanship and a professional PE Tech Foam team, which can provide a variety of advanced project solutions for customers to choose from.

-

06-07 2021

Another XPE foaming machine of Qinding Company is about to be installed in the customer's factory

Recently, a leading XPE product company located in Guangdong, China, in order to meet the rapidly growing business, the XPE foaming machine produced by our company recently purchased and completed and shipped on May 25. After arriving at the customer site, the installation engineers of our company worked day and night. After 15 consecutive days of intense work, this set of XPE foaming machine has completed the installation of the host.

-

05-28 2021

Another set of XPE foaming machine of Qin Ding Company is about to be completed

Recently, a leading XPE product company located in Guangdong, China, in order to meet the rapidly growing business, the XPE foaming machine produced by our company, which was purchased recently, is about to complete factory production and enter the delivery stage.

-

05-21 2021

Qin Ding Company's Precision Parts Division officially opened for business

After nearly three months of intense deployment, the precision parts division of Qin Ding Company officially opened its doors, accepting international and domestic precision machined parts. The Precision Division is located in Tangxi Town, Ningbo, with convenient transportation. The factory covers an area of 2,300 square meters, with dozens of various processing and testing machinery, complete processing machinery and advanced testing methods. The team led by General Manager Jim Yao has been engaged in the precision machining industry for more than ten years and has rich experience in machining site management and advanced industry knowledge. Congratulations on the grand opening of the Precision Division of Qin Ding Company, and welcome domestic and foreign customers.