-

05-21 2021

Qin Ding Company's Precision Parts Division officially opened for business

After nearly three months of intense deployment, the precision parts division of Qin Ding Company officially opened its doors, accepting international and domestic precision machined parts. The Precision Division is located in Tangxi Town, Ningbo, with convenient transportation. The factory covers an area of 2,300 square meters, with dozens of various processing and testing machinery, complete processing machinery and advanced testing methods. The team led by General Manager Jim Yao has been engaged in the precision machining industry for more than ten years and has rich experience in machining site management and advanced industry knowledge. Congratulations on the grand opening of the Precision Division of Qin Ding Company, and welcome domestic and foreign customers.

-

05-17 2021

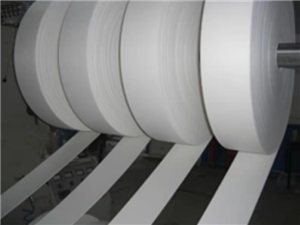

Application examples of IXPE foam products in the tape sealing industry

IXPE foam products are widely used in all walks of life due to their superior comprehensive performance. Among them, there are many applications in the tape sealing industry.

-

05-12 2021

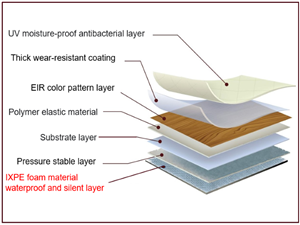

Application details of IXPE floor mats

IXPE floor mat is a silent mat. It is a foamed film made of high-pressure polyethylene (LDPE), cross-linked by electron irradiation, and foamed with an IXPE foaming machine. Ultra-fine foam provides cushioning and shock absorption. The composite aluminized film can play a role in moisture-proof. Installed under the floor, not only can absorb vibration and sound insulation, but also keep warm for floor heating. If special ingredients are added when making IXPE foam, IXPE foaming material with antibacterial, mildew, and flame retardant functions can also be made.

-

05-11 2021

Qin Ding’s XPE/IXPE foaming machine prices will be adjusted at the beginning of next month based on the raw material market prices

Qin Ding Company serves the XPE foam, IXPE foam and Crosslink foam industries, and has two XPE/IXPE foaming machine manufacturing bases and a foaming mat manufacturing plant. Qin Ding has advanced Crosslink Foam technology and craftsmanship, and has a professional PE Tech Foam team. The company's XPE/IXPE foaming machine factory produces more than ten XPE/IXPE foaming lines per year, and uses relatively large quantities of steel and copper materials, which are affected by the market price fluctuations this time. To this end, the company’s leaders made a decision: From June 1, 2021, according to the current market prices of raw materials, the price of XPE foaming machine is expected to increase by 20~30%, and the price of IXPE foaming machine is expected to increase by 15%~25%.

-

05-10 2021

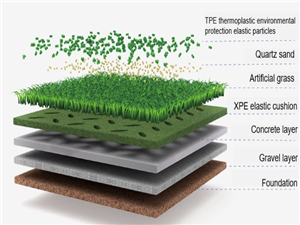

Application details of XPE foam and IXPE foam material in lawn mats

XPE foaming machine (main machine including pelletizing unit, master chip extruding unit, XPE foaming furnace unit) is used to produce XPE coils. The thickness of this kind of coil is generally 8~12mm, the width is mostly 1.5m, the length of a single coil is generally 72m, and the XPE coil has a magnification of 30~35 times. It requires fine foam cells and good resilience. The colors are mainly green XPE foam and milky white XPE foam, some of them will use natural XPE foam, and black XPE foam will be used less.

-

05-08 2021

Another IXPE foaming machine produced by Qin Ding will be put into production in South China

The IXPE foaming machine purchased by the company is a very mature product of Qin Ding, and it has already operated many in China and abroad. This IXPE foaming machine includes three parts: a pelletizing unit, a master chip extruding unit, and an electric heating IXPE foaming furnace. The electronic radiation cross-linking process of IXPE mother film is not within the scope of delivery of this project due to the large investment and difficult administrative approval. Buyers will use outsourcing processing in this process in the future production.

-

05-07 2021

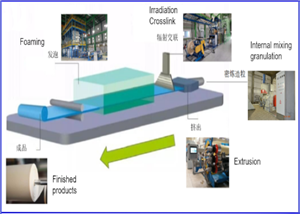

IXPE foamed coil production process introduction

The production of IXPE foaming products is a sophisticated and complex process. Every link is indispensable and very important. If a perfect IXPE foaming product is to be produced, process control is very important. Qin Ding is a professional IXPE foaming machine provider. It has more than 10 years of first-line production experience and has accumulated rich experience. It can provide customers with unique help from raw material selection, site planning, equipment selection, formula and technology, and personnel training.

-

05-06 2021

The business of Qin Ding Company has improved, and the first-line workshops have frequent good news

Qin Ding serves the PE teach foam and Crosslink foam industries, and has multiple foaming machine manufacturing bases and foaming mat manufacturing plants. The company's Sunhigh brand Floating mat, PE Tech Foam Coil, Crosslink Foam Floating Pad, Crosslink Foam Children Climbing Mat products have been sold on Amazon. The IXPE foam machine and XPE foam machine produced by the head office are sold at home and abroad. Qin Ding has advanced Crosslink Foam technology and craftsmanship and a professional PE Tech Foam team, which can provide a variety of advanced project solutions for customers to choose from. Welcome new and old customers to call or write to negotiate.

-

05-04 2021

Qin Ding Company May 1st International Labor Day Work Arrangement

Qin Ding serves the PE teach foam and Crosslink foam industries, and has multiple processing plants and companies. The company’s Sunhigh brand PE Tech Foam Coil, Crosslink Foam Floating Pad, Crosslink Foam Children Climbing Mat products have been sold on Amazon, and produced IXPE foam. Crosslink Foam Line such as machine and XPE foam machine are sold at home and abroad. Qin Ding has advanced Crosslink Foam technology and craftsmanship and a professional PE Tech Foam team, which can provide a variety of advanced project solutions for customers to choose from. Welcome new and old customers to call or write to negotiate.

-

04-29 2021

Summary of the application of XPE/IXPE foam material in baby mats

XPE foam material and IXPE foam material have been widely used in the baby industry due to their superior comprehensive performance, health and environmental protection, softness and rigidity.